Hot moulding is…

Hot moulding is a faster and cheaper method of working that allows us to produce buckles and fashion accessories in a precise manner, guaranteeing the quality of the product.

Knowing the techniques used to manufacture a product allows fashion accessory manufacturers to live their production. Chain to the fullest and to rely on a commercial partner that carries out these processes have for years been very important for the growth of its business.

What is the hot forging technique?

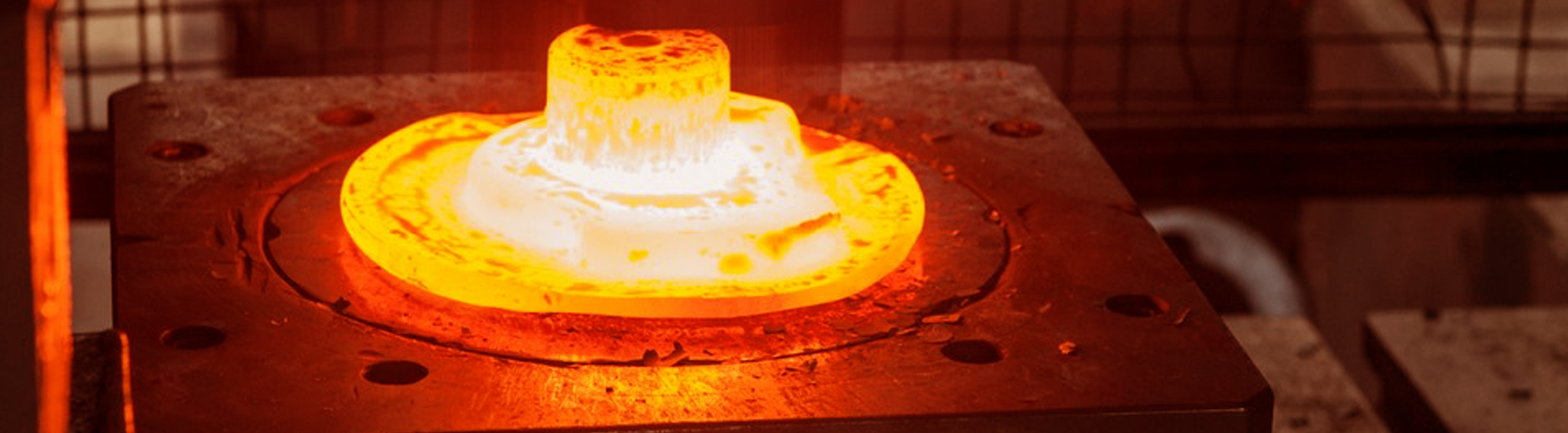

The hot moulding technique allows to modify in a natural way the structural characteristics of metals allowing a better adaptation to

the shape of the buckle, thus obtaining a product, resistant to tensions to which it can be subjected during the use of the final

assemblies.

Specifically, the metal material is processed in the form of solid rounds, placed in an oven are brought to a heat point called

“cherry red”.

A robot takes the individual rounds and inserts them into a steel mould.

and then what?

Once the buckle has been printed, it is cut into its contours and then barrel, sanded and polished strictly by hand. In the end, we

have the galvanisation.

Hot moulding therefore allows to obtain excellent products, with high quality standards compared to any other

melting process.

To know all the details of the production of buckles and fashion accessories with hot stamping, contact us.